A research team in San Diego has developed a new method for recycling lithium-ion batteries in California as electric vehicle and energy storage sales boom across the world.

A research team in San Diego says it has developed a new method for recycling lithium-ion batteries in California as electric vehicle and energy storage sales boom across the world.

University of California, San Diego researchers demonstrated how to deactivate, dismantle and separate used battery components to recover more than 90% of cathode and anode active materials. The recycled materials were then tested and found to operate comparably to new battery materials, the researchers said in an Oct. 20 report to the California Energy Commission.

More than 22 million pounds of lithium-ion batteries will be ready for recycling in California in 2027. Without sustainable management, the rapid consumption of batteries “risks resource shortages and price volatility for critical materials like lithium, cobalt and nickel — key contributors to battery costs,” researchers said in the report.

Recycling and recovery of these valuable materials, which can make up 45 to 60% of battery manufacturing costs, are “essential to lowering production expenses and reducing the lifecycle environmental hazards posed by improper disposal,” the report says.

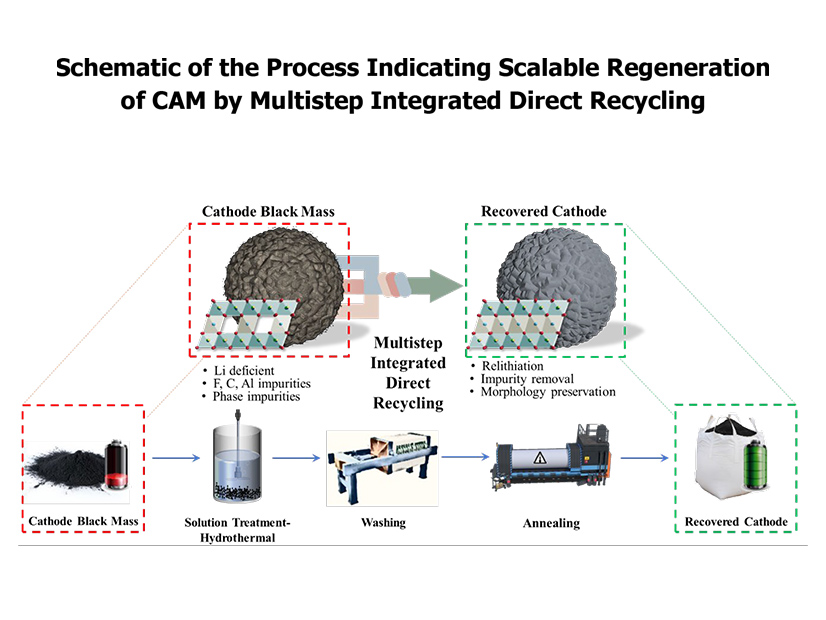

In their experiment, researchers created a direct recycling method to physically separate and recover cathode and anode battery materials. They de-energized 25 pounds of lithium-ion battery cells with more than 1,000 ampere-hours of total capacity. The battery cells contained different chemistries, types, ages and sources, such as from EVs and electronic devices.

The direct recycling method is one of three primary battery recycling methods, the other two being pyrometallurgical recycling and hydrometallurgical recycling.

Pyrometallurgical recycling requires high-temperature smelting that uses large amounts of energy and generates significant pollutants, while hydrometallurgical recycling requires strong acids and oxidants, leading to “extensive treatment to address environmental and safety concerns,” the report says.

Direct recycling could save up to $17 million and reduce energy consumption by up to 1,285 GWh by 2030, compared to pyrometallurgical and hydrometallurgical recycling, the report says.

After proving their direct recycling approach worked, researchers increased the volume of batteries in each batch from 100 g to 5 kg.

California currently does not have a large-scale lithium battery recycling facility. As they grow old and fizzle out, used battery volumes will continue to increase, and the costs of transporting them out of the state will become too burdensome and expensive, the report says.

Battery manufacturers and automakers could leverage an in-state recycling pathway to “enhance efficiency, minimize waste and support the broader electrification of the automotive industry,” the report says.

The results of the project could help future research teams or companies build a 100-kg scale recycling facility. Doing so could be the next step toward building a commercial facility in the state, the report says. UC San Diego researchers have been allocated $10 million by the Department of Energy to continue to increase the scale of the direct recycling method.