SERC Reliability held a two-day Operations & Planning (O&P) Compliance Webinar Nov. 10-11, with discussions on operations under the coronavirus pandemic, recent enforcement trends and 2021’s enforcement priorities. Below are the highlights of what we heard.

‘Focusing on the Why’

SERC and its stakeholders have taken advantage of the shutdown of in-person meetings this year to improve their ability to address small reliability issues as well as reconsidering whether their practices are in line with their strategic goals, CEO Jason Blake told 175 people who turned out Tuesday for the beginning of the annual meeting.

“It’s been impressive the way our industry has been able to navigate these unusual times,” Blake said. “We have the pandemic, a record-breaking hurricane season, social unrest and then the traditional things that challenge us, such as the evolving nature of the grid itself and increased cyber activity.”

Challenges bring opportunities by forcing people to rethink their routine ways of working, Blake said.

“Taking this approach allows you to unleash all types of potential and creativity,” he said. “The point is the criticality of focusing on the why. Why are we here? Why do I have this program in place back at my shop? Why is this standard a standard? What is its purpose?”

Blake said the shutdown has shown SERC the value of self-logging and remote audits, which, “if deployed properly,” can be a great tool for the organization even without a pandemic.

“The thing I’m very proud of is how our productivity has remained so high,” Blake said. “We’re taking this opportunity to improve our programs, understanding that the way we focus ourselves has a ripple effect across industry … and unresolved issues create a bottleneck. We have been working very hard to drive even further enhancements … make sure we have robust mitigation in place, as well as to properly resolve noncompliance based around risk.”

For the first time in years, SERC staff are regularly resolving issues faster than they come in the door.

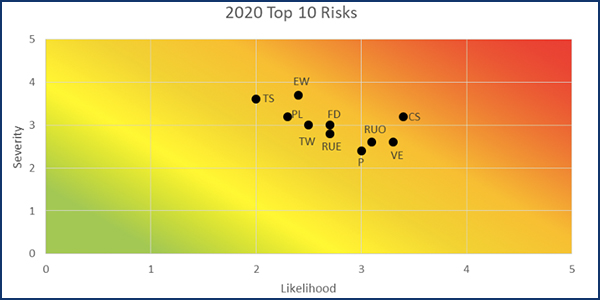

Blake touted SERC’s 2020 Reliability Risk Report issued in September, which was drafted by the Reliability Risk Working Group.

The report identifies the top risks to focus on and prioritizes them, which “really demonstrates our commitment to be a data-driven, risk-based organization,” Blake said.

2021 Enforcement Priorities

The COVID-19 pandemic has affected compliance monitoring mainly by forcing it off-site, a precaution that will now extend through the first quarter of 2021, said Todd Curl, SERC senior manager of compliance monitoring.

Having replaced the former SPP and Florida Reliability Coordinating Council regional entities in 2018 and 2019, respectively, SERC now has about 264 registered entities in its footprint, Curl said.

“We have on the schedule a total of 62 CIP [critical infrastructure protection] and O&P audits for 2021, and also four spot checks scheduled in addition to those audits, so that gives you an idea of what we’re looking at for next year,” Curl said.

While no audits will be done on-site through the first quarter, some activities need to be done on-site, especially around some aspects of NERC reliability standards CIP-014 and FAC-008, the latter relating to facilities, design, connections and maintenance, he said.

Curl also gave a presentation on the ERO’s 2021 Compliance Monitoring and Enforcement Program (CMEP) Implementation Plan, which is focused on:

- remote connectivity and supply chain (CIP-005-6, CIP-007-6, CIP-010-3 and CIP-013-1);

- poor quality models impacting planning and operations (MOD-026-1, MOD-027-1 and MOD-033-1);

- loss of major transmission equipment with extended lead times (TPL-001-4);

- inadequate real-time analysis during tool and data outages (IRO-008-2 and TOP-001-4);

- determination and prevention of misoperations (PRC-004-5 and PRC-027-2); and

- gaps in program execution (CIP-010-2, FAC-003-4, FAC-008-3 and PRC-005-6).

The plan “looks at ERO-wide risk,” Curl said. “Each region beyond that needs to focus on region-specific risks.”

As a result, Curl said, SERC auditors will continue their focus on CIP-002, although it is no longer among the ERO’s priorities.

“As the [plan] was being discussed by NERC and the regions and we were talking about what needs to stay in, what needs to come out, what needs to go in for the first time … it was SERC and one other region who still seem to see CIP-002 as high risk. All the other regions feel like it was a much lower risk than in the past,” Curl said. “We’re going to continue for at least another year in 2021 to focus on CIP-002.”

SERC’s 2020 Reliability Risk Report cited the standard as an example of gaps in program execution. The standard is designed to ensure entities maintain complex programs that handle large amounts of data, such as accurate inventories of equipment, following asset transfers and the addition of new equipment.

FAC-008 Enforcement Trends

SERC legal counsel Dulce Plaza gave a briefing on enforcement trends regarding standard FAC-008.

FAC-008-3 became effective on Jan. 1, 2013, when FAC-008-1 and FAC-009-1 were retired. FAC-008-3 R6, which is very similar to FAC-009-1 R1, requires each transmission owner and generator owner to have facility ratings consistent with their ratings methodology.

Facility ratings were a NERC “area of focus” in the 2019 and 2020 ERO Enterprise CMEP Implementation Plans because of compliance engagements and self-report findings that identified potential reliability gaps. The 2020 SERC Reliability Risk Report by the RE’s Engineering Risk Committee identified FAC-008 as a major risk.

Plaza said FAC-009-1 and FAC-008-3 remain two of the most frequently violated O&P standards, representing 13% of SERC’s current O&P violation inventory.

Between Jan. 1, 2013, and Aug. 31, 2020, the region identified 33 violations of FAC-009-1 R1 and 24 violations of FAC-008-3 R6, most of them from self-reports. More than 50% were considered “minimal” risk and less than 10% considered “serious” risks.

Most discrepancies in facility ratings were the result of ineffective asset identification or change management controls, Plaza said.

She said some entities failed to correctly identify all their equipment in the field at the beginning of the enforceable period for FAC-008-3 and had not completed a “walk-down” of their facilities to verify if the equipment in the field was what was included on the one-line diagrams and facility ratings database. Thus, some noncompliance start dates for issues initially identified as FAC-008-3 violations extend back to 2007 and were processed under FAC-009-1.

Plaza also cited entities that consolidated equipment in the database rather than listing equipment individually, resulting in a single rating for different pieces of equipment. Entities also failed to remove retired devices from their database and diagrams in some instances.

“I would say based on the data, we are seeing improvements” in compliance, Plaza said. “An uptick in violations doesn’t mean that we’re doing worse. It just means that we’re finding things that we didn’t find before, especially during audits.”

Mike Kuhl, SERC’s manager of O&P monitoring, said common errors are one-line diagrams that fail to include all switches and jumpers. “The transformer ratings — your large pieces of equipment — usually they’re good. But a lot of times, there’s a component that can be easily overlooked and catch you.”

Kuhl said that although the standard requires entities to consider all equipment rather than just the most limiting, “we’re not expecting absolute compliance from an auditing perspective.”

“If there’s one or two [violations, and] an auditor exercising professional discretion [determines] that there is reasonable assurance of compliance overall, we’re not going to call that out,” he said.

Curl said FAC-008 is one standard for which off-site monitoring is a handicap. “We’re auditing FAC-008 off-site as best we can to have reasonable assurance, but there may be some time after COVID is over [that] we may do a follow-up spot check,” he said.

Data to Include in Self Reports and Mitigation Plans

Jimmy Cline, SERC managing counsel, and Todd Beam, SERC manager of risk assessment and mitigation, gave a presentation on data that should be included in self-reports and mitigation plans.

Beam said self-reports should be as detailed as possible at the time of submission. “Let us know how the issue was identified: What was occurring that led to the discovery. Identify any internal controls … associated with the identification of the violation. Did it help identify [the violation or] did an internal control fail? Detail that out for us.”

He said self-reports also should identify what share of the total population in the program was affected. “Was it one out of 10,000, or 900 out of 1,000? That helps us understand the magnitude of the issue.”

Identification of the causes of noncompliance also should be detailed, Beam said.

“You can’t say, ‘The procedure was deficient,’ or perhaps, ‘An individual required training,’” he said. “We’re going to have to understand what was specifically deficient in the procedure. What needed to be added that wasn’t there? What was possibly misinterpreted or misapplied? Same with training: Why was the training not already provided? What was the deficiency? Identify the aspects of training that require improvement: the frequency of training; the training topics. Help us understand that.”

SERC expects self-reports within 90 days of discovery. “If there’s a delay, anticipate some questions, because we’re going to want to know why,” Beam continued. “If you as an entity are having difficulty in meeting that 90-day criteria, things to ask yourself: Are your internal business processes or review cycles too complex? … Do you have the proper staffing levels? … Are the necessary skill sets available?”

Winter Weather Plan

Tim Hattaway, energy service manager for PowerSouth Energy Cooperative, presented a winter weather plan for its service territory providing wholesale power to 20 distribution members in Alabama and northwest Florida.

PowerSouth owns and operates 1,680 MW of generation, mostly natural gas-fired but including the only compressed air energy storage facility in the country, a 110-MW facility in McIntosh, Ala., Hattaway said.

The cooperative, a registered balancing authority, is much better versed in hurricane preparedness than in cold-weather operations, “because we really got hammered with hurricanes, this year especially,” he said. “We don’t have a lot of cold, freezing weather, but we do deal with weather in the Gulf of Mexico.”

The cooperative is a winter-peaking system, with approximately 85% residential load, and generally sees fewer than 30 hours per year of temperatures below 25 degrees Fahrenheit. But after that figure climbed over 110 hours in the polar vortex of 2014, it hired an outside engineering firm to help.

“They performed a detailed analysis on all of our generators, even our small hydro facilities that are 1-MW units … and they highlighted our heat tracing, our insulation, things like that,” Hattaway said.

One finding was that generation unit operators tended to face cold weather by adding more heat tracing — electric cables to heat a pipe — rather than by trying to understand how to winterize units properly. For example, the study taught them that wet insulation causes pipes to freeze approximately two times faster than with dry insulation, and that even a small amount of moisture in instrumentation lines can cause false readings and unit trips.

It took the company over a year to go over the 800-page report and implement all its recommendations, he said.

One questioner asked whether the co-op ever experienced units that would not start, and if so, how long it took to fix the issue.

“One reason we like the day-ahead start-up is because if we have an issue with a unit starting, and … if we stuck to our economic dispatch plan, we might call on that unit at 3 in the morning, but if it doesn’t start at 3, we’ve only got about an hour to resolve the problem,” Hattaway said.

Typically, the company has been able to get the units online in time for when needed the following morning, and unit operators much prefer a good lead time on getting started, he said.

“We also have a 20-day or 25-day start-up procedure where we start units just to make sure they’re in running order,” Hattaway said.

Registered Entity Forum Election

Ballots are due Nov. 13 in the vote to fill four open positions on SERC’s Registered Entity Forum Steering Committee for two-year terms. The committee requires at least one representative with a CIP background.

The committee, which meets quarterly, provides a conduit to SERC staff and an opportunity for discussion among registered entities regarding reliability and compliance issues, including sharing lessons learned and best practices. Registered entities that want to ask SERC questions without subjecting themselves to scrutiny can approach a committee member, who can ask the question while maintaining the RE’s anonymity.

Ballots were sent to primary compliance contacts Nov. 5. Those elected will be notified the week of Nov. 23 and announced in the SERC Transmission newsletter in December.