President Biden on Tuesday ramped up efforts to build out U.S. clean energy supply chains with a series of announcements focused on the mining, refining and recycling of critical minerals, including the lithium and cobalt used in batteries for energy storage and electric vehicles.

“China has spent several years cornering the market on many of the materials that power [these] technologies,” Biden said during a virtual roundtable with state and federal officials and corporate executives. “That’s why I committed us to build a clean energy supply chain stamped ‘Made in America’ … using products, parts and materials, as well as minerals right here that are in the United States of America.”

Biden’s first announcement was a $35 million grant from the Department of Defense, which will help MP Materials in Mountain Pass, Calif., build out an end-to-end supply chain to refine and process rare earth minerals needed for the magnets used in EVs and wind turbines. According to a White House fact sheet, China controls 87% of the global market for these magnets.

MP is planning to invest another $700 million in the project over the next two years, said CEO James Litinsky. In December, the company announced it had signed a long-term agreement with General Motors to provide magnets for its EVs, including the GMC Hummer EV and the Chevrolet Silverado EV.

Litinsky noted that the MP facility will be an environmentally friendly operation, with a “dry tailing process” that recycles 95% of the water it uses. By 2025, the facility could be producing magnets for 500,000 EVs per year, he said.

The other big announcement came from BHE Renewables, which will soon start operations on the first phase of a demonstration project that will extract lithium from geothermal brine at the company’s geothermal plants located at the Salton Sea in Imperial County, Calif. The second phase of the project, which will refine the lithium for battery manufacture, is being funded in part by a $14.9 million grant from the Department of Energy, which is being matched by a similar amount from BHE.

“If both these demonstration projects are successful, we would then be in a position to begin construction of our first commercial plant in 2024 and by 2026 be commercially extracting lithium from our geothermal brine,” said Alicia Knapp, president and CEO of BHE.

According to the White House fact sheet, BHE’s commercial-scale lithium extraction in Imperial County could produce 90,000 metric tons of lithium per year.

The BHE projects have been the centerpiece of California’s efforts to create a “Lithium Valley” in Imperial County, which has historically high unemployment rates and was hard hit by the COVID-19 pandemic. BHE has committed $25,000 for scholarships to support science, technology, engineering and math (STEM) education in the county, Knapp said.

The company is also working with local schools to develop training programs, internships and “hands-on opportunities at our site to help prepare local residents for future careers in geothermal or lithium,” she said.

California Gov. Gavin Newsom called the development of a lithium supply chain in Imperial County “a hinge moment” and potential game changer. The state intends to follow up on the local efforts with a “community benefits package focusing not just on the economic opportunity but making sure the growth and inclusion strategies include local hires [and] local benefits in a sustainable way,” he said.

Circular Supply Chains

While largely overshadowed by Russia’s invasion of Ukraine, the roundtable and accompanying announcements were intended to mark the one-year anniversary of Biden’s Executive Order 14017, which ordered a multiagency evaluation of vulnerabilities in the U.S. supply chain.

Building out domestic supply chains is critical for Biden to achieve his goal of a 100% clean energy electric system by 2035 and a net-zero economy by 2050.

The International Energy Agency has estimated that lithium demand could see a 40-fold increase by 2040, with a 20-fold increase projected for cobalt and nickel.

The report issued after E.O. 14017 underlined the risks of China’s dominance in lithium-ion battery supply chains and called for an “an end-to-end coordinated supply chain strategy.”

The White House fact sheet included other announcements not mentioned during the roundtable.

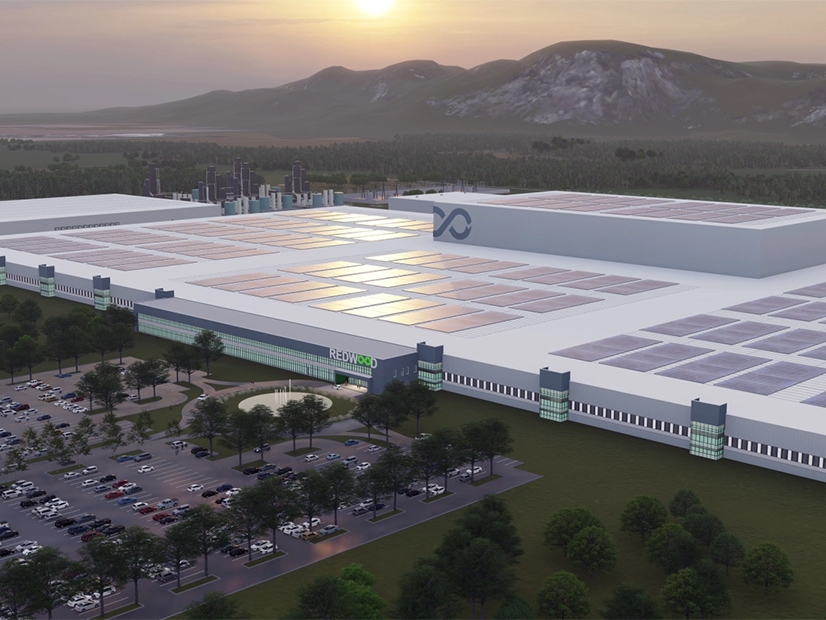

Nevada-based Redwood Materials is partnering with Volvo and Ford on a pilot project that will collect and recycle end-of-life EV batteries to extract lithium, cobalt, nickel and graphite. Closing the loop, the company is also partnering with Ford on a second recycling plant in Tennessee and will begin construction on a cathode manufacturing plant in Nevada this year.

According to a recent press release, the company’s goal is to create a circular supply chain that will produce enough battery components to power 5 million EVs by 2030.

In addition, DOE will invest another $140 million from the Infrastructure Investment and Jobs Act to fund a demonstration project to help build out supply chains for rare earth elements (REEs) and critical minerals (CMs). According to a request for information released Feb. 14, the goal of the project is to design, construct and operate “a first-of-a-kind, domestic demonstration facility that produces REEs and CMs from domestic resources that include unconventional and secondary sources, such as coal waste materials.”

“Applying next-generation technology to convert legacy fossil fuel waste into a domestic source of critical minerals needed to strengthen our supply chains is a win-win,” Energy Secretary Jennifer Granholm said in a statement released with the RFI. “We are moving ideas from the lab to the commercial stage and demonstrating how America can compete for the global supply chain to meet the growing demand for clean energy technology.”

The administration is also launching an effort to update the 150-year-old Mining Law of 1872, which still governs the mining of most critical minerals on federal lands. The Department of the Interior on Tuesday announced the formation of an interagency working group that will focus on legislative and regulatory changes to mine permitting.

The department issued a list of fundamental principles that, the White House said, “will promote responsible mining under strong social, environmental and labor standards that avoids the historic injustice that too many mining operations have left behind.”

‘A Tall Order’

The response to Tuesday’s announcement from energy groups was mixed.

Andrew Reagan, executive director of the industry advocacy group, Clean Energy for America, praised Biden for delivering on his efforts to ramp up clean energy supply chains. “Producing more of these critical minerals and materials in America will mean even more families in America will enjoy the benefits of clean energy, sooner and swifter,” he said.

Sheila Hollis, acting executive director of the United States Energy Association, called the announcements “a shot in the arm” for U.S. clean energy supply chains, but she also pointed to significant obstacles ahead. With global supply chains already set up, it will be “a tall order” for the U.S. to develop the supplies of critical minerals it will need and build out new processing and manufacturing facilities while it is still reliant on imports, Hollis said.

“Multibillion-dollar supply chains do not move overnight,” MP Materials’ Litinsky agreed. “It’s going to require capital. It’s going to require perseverance. It’s going to require strong coordination between the upstream and downstream, and most importantly it’s going to require a commitment from leadership across the board.”