The Department of Energy on Wednesday awarded 20 companies $2.8 billion to supply minerals critical to battery production and bolster domestic manufacture of batteries for electric vehicles and the grid.

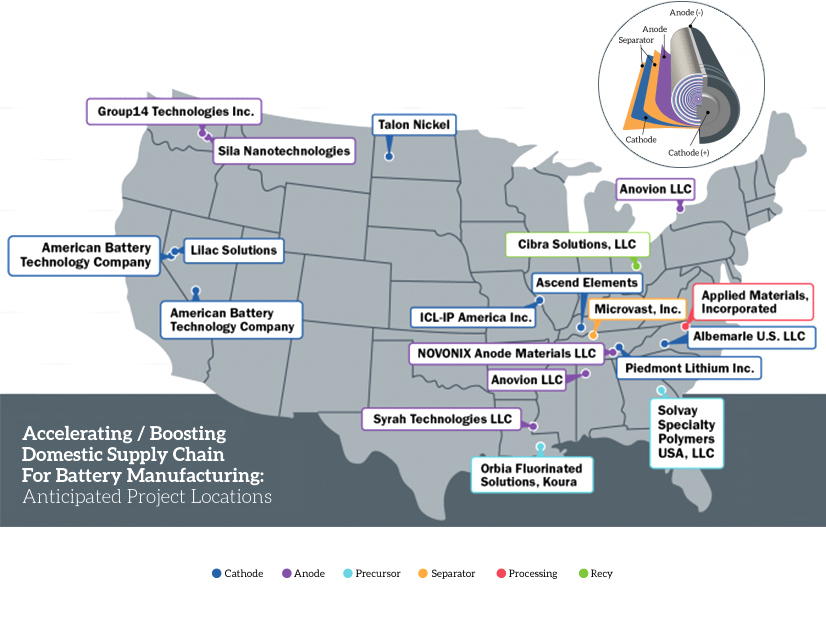

The grants are the first round of $7 billion in DOE funding for batteries from last year’s $1.2 trillion Bipartisan Infrastructure Law, which included $62 billion for energy programs. The awardees will build or expand facilities in 12 states to manufacture battery components, including from recycled materials, and extract and process battery materials such as lithium and graphite, DOE said in a news release.

“This is truly a remarkable time for manufacturing in America, as President Biden’s agenda and historic investments supercharge the private sector to ensure our clean energy future is American-made,” Energy Secretary Jennifer Granholm said in the statement. “Producing advanced batteries and components here at home will accelerate the transition away from fossil fuels to meet the strong demand for electric vehicles.”

Sales of plug-in EVs have tripled since Biden took office, but the U.S. remains too dependent on other nations for critical minerals needed to produce EV batteries, mainly lithium, cobalt, nickel and graphite, DOE said.

“China controls the supply chains for many of these key inputs,” it said.

The grants are intended to alter that imbalance. All are matched or exceeded by company investments “to leverage a total of more than $9 billion,” according to DOE.

The largest award of $316 million went to Ascend Elements to establish industrial-scale separation of cathode materials from spent lithium-ion batteries and produce “precursor cathode active materials and metal salts to support domestic production of cathode active material (CAM),” DOE said in a fact sheet on the project. CAM can then be used in new lithium-ion batteries for EVs and energy storage systems, it said.

A new plant in Hopkinsville, Ky., will supply enough materials for 250,000 EVs annually, according to DOE. Ascend received another $164 million to design and construct the CAM plant.

With a $115 million DOE grant, Talon Nickel plans to construct a battery minerals processing facility in central North Dakota to process nickel ore for battery production. The company has an agreement with Tesla to supply 75,000 metric tons of nickel in concentrate along with copper, cobalt and iron in nickel and copper concentrates for “multiple battery chemistries,” DOE said.

“This process improves yield and metal byproduct utilization relative to legacy processing of nickel ores,” it said.

Talon CEO Henri van Rooyen said in a statement Wednesday that the “national urgency and the target date for nickel and iron production set within our Tesla-Talon supply agreement required an innovative approach to bring a new domestic source of battery minerals into production during a period of global battery-grade nickel deficits. Today’s announcement is a clear recognition that production of domestic nickel and other battery minerals is a national priority.”

In McMinn County, Tenn., Piedmont Lithium will use a $142 million grant to help build its $600 million Tennessee Lithium project, “which aims to expand the U.S. supply of lithium hydroxide by 30,000 metric tons per year,” the company said in a news release. “Lithium hydroxide is a key component of high energy density, long-range, EV batteries,” it said.

“We are pleased that the DOE has chosen to support our Tennessee Lithium project, and we are committed to being responsible stewards of these grant funds,” Piedmont COO Patrick Brindle said in the statement. “This funding will enable us to accelerate detailed engineering and place orders for long-lead items.”

Construction at the Tennessee Lithium project is expected to start next year, with production beginning in 2025, the company said.

‘Reliable’ and ‘Sustainable’ Supply Chain

Other projects funded include the first large-scale lithium electrolyte salt production facility in the U.S.; an “electrode binder facility capable of supplying 45% of the anticipated domestic demand for binders for EV batteries in 2030”; the nation’s first commercial-scale silicon oxide facilities, which will produce materials for an estimated 600,000 EV batteries annually; and the first lithium iron phosphate cathode facility in the U.S., DOE said.

In total, Wednesday’s first-phase funding will help supply enough battery-grade lithium for “2 million EVs per year, enough graphite for 1.2 million EVs annually and enough nickel for 400,000 EVs,” DOE said. The grants will promote creation of 8,000 jobs including 5,000 permanent jobs, many of them in or near disadvantage communities, it said.

The Biden administration wants electric vehicles to make up half of all new vehicle sales by 2030 and to transition to a net-zero emissions economy by 2050, the department noted.

Toward that end, the Biden administration announced Wednesday it was launching the American Battery Material Initiative, a “new whole-of-government effort to secure a reliable and sustainable supply of the critical minerals that power everything from electric vehicles to homes to defense systems,” the White House said in a fact sheet. “The American Battery Materials Initiative will be led by a White House steering committee and coordinated by the Department of Energy with support from the Department of the Interior.”

“The Initiative will work through the Partnership for Global Infrastructure and Investment, and leverage ongoing work by the Department of State, to work with partners and allies to strengthen critical mineral supply chains globally, and it will leverage and maximize ongoing efforts throughout the U.S. government to meet resource requirements and bolster energy security,” it said.