Using renewable natural gas (RNG) as a feedstock offers hydrogen producers a shortcut to claiming the full federal tax credit created by the Inflation Reduction Act (IRA) to incentivize hydrogen production.

That translates into a tax credit of $3/kg of clean hydrogen produced, or 2.6 cents/kWh of power generated using that clean hydrogen as fuel.

RNG is made from landfill gas or from biogas produced by anaerobic digesters that process municipal sewage or animal manure. Indistinguishable from fossil-based natural gas, RNG is also now more valuable as a fuel itself because the IRA expanded the federal production tax credit (PTC) to include biogas projects that begin construction before 2025. Previously, the PTC applied to only wind and solar projects.

Even before the IRA passed last year, interest in biogas had increased among companies looking for ways to increase their environmental commitments by purchasing electricity made by biogas-powered generators or by purchasing carbon credits associated with biogas.

The potential for producing hydrogen by steam reforming RNG has burnished the image of biogas as an important, if interim, fuel that could be critical to boosting hydrogen production as the industry works to build the massive numbers of electrolyzers needed to make clean hydrogen from water and determine where along the nation’s grid to locate them.

The idea has sparked the interest of biogas producers, as evidenced last week when the American Biogas Council (ABC) organized a webinar to announce it had retained Iowa-based engineering company EcoEngineers to create an accounting methodology as a tool to help biogas producers understand carbon accounting in fuels.

About 1,000 organizations registered for the webinar, the highest ever for an ABC event, said Patrick Serfass, the trade group’s executive director.

Getting the Right Score

A day after the webinar, an EcoEngineers representative participating in an unrelated online biogas event sponsored by Spain-based ATA Insights explained the importance of carbon accounting to companies trying to qualify for a tax credit under the IRA.

“I’m sure most of us are aware that the carbon intensity score [of hydrogen] is key,” said Tanya Peacock, a managing director at EcoEngineers.

“One way of making sure that you can maximize the available value from all of these [federal] credits and incentives is to make sure that you design your projects to achieve, from the outset, your desired target CI score,” she said.

To receive the full tax credit, $3/kg of hydrogen produced over 10 years, a hydrogen producer must prove the technology used to make that single kilogram of hydrogen generates no more than .45 kilograms of CO2, she explained.

Most hydrogen produced today from natural gas uses high heat and high-pressure steam to break the molecular bonds of methane (CH4), releasing the hydrogen and allowing the carbon to combine with oxygen in ambient air. It’s a process that fails the strict CI score but could work financially, say some analysts, if that CO2 is captured and sequestered — or if steam methane reforming could be made more efficient.

Gabriel Olson, former innovation director at SoCalGas and now director of carbon strategy and head of hydrogen markets for Texas-based BayoTech Hydrogen, said his company produces hydrogen with steam methane reforming but uses 20% to 30% less energy, thanks to a modular steam methane reformer developed by Sandia National Laboratory.

More importantly, BayoTech also uses RNG rather than conventional fossil gas as a portion of its feedstock, making its hydrogen competitive, he said, adding that the process does not require 100% RNG.

Using 100% dairy-sourced RNG in the modular steam reformer produces hydrogen with a carbon intensity (CI) of -300, he said, well under the minimum CI required by the IRA.

“That might be amazing and impressive, but it’d be kind of expensive, because you’re using a lot of a deeply negative [CI] and a highly valuable feedstock,” Olson said. “What we do is more cost-effective,” by using a blend of 30% dairy RNG and 70% pipeline natural gas.

“We’re effectively able to [produce] a cost-effective hydrogen product that’s both valuable and eligible for the incentive credits that are available,” including the PTC, he said.

“We see RNG as kind of the linchpin for doing this cost-effectively,” Olson said. “There are other pathways — carbon capture and things like that. But RNG for us is the most cost-effective, and the most flexible in terms of deployment, for multiple facilities in multiple locations. We see it as a great way to offset the fossil natural gas that we typically use as a feedstock.”

‘Next Wave’

Another company with a similar strategy that should have little trouble meeting federal CI standards is Illinois-based Amp Americas, which began producing RNG in 2011 from cow manure as a fuel for an electricity producer but then turned to providing the gas to an Indiana dairy for use as a fuel in its delivery trucks. The company then began producing and selling dairy-based RNG as a motor fuel in California.

“In 2022, we produced 1.3 million BTUs of renewable natural gas from dairy manure. That’s about 11% of market share of total dairy gas produced in the United States. The gas has an ultra-low CI net … a -250 to -300 score,” said Andy Dvoracek, the company’s vice president of business development.

The calculation for that ultra-low CI rests on how much methane the company’s operation has prevented from entering the atmosphere had the manure not been converted to biogas in an anaerobic digester, Dvoracek said.

<img src=”https://rtowww.com/wp-content/uploads/2023/06/140620231686776292.jpeg” data-first-key=”caption” data-second-key=”credit” data-caption=”Renewable natural gas made in an anaerobic digester from cow manure has a negative carbon score since the methane produced in the digester is captured and hydrogen produced from that methane qualifies for a maximum federal tax credit.” data-caption-html=”Renewable natural gas made in an anaerobic digester from cow manure has a negative carbon score since the methane produced in the digester is captured and hydrogen produced from that methane qualifies for a maximum federal tax credit.” data-credit=”

” data-description=”Renewable natural gas made in an anaerobic digester from cow manure has a negative carbon score since the methane produced in the digester is captured and hydrogen produced from that methane qualifies for a maximum federal tax credit.” data-id=”5548″ style=”margin: auto;” alt=”Generating-Hydrogen-from-RNG-(BayoTech-Hydrogen)-Content.jpg” data-uuid=”YTAtOTMwOTc=”>Renewable natural gas made in an anaerobic digester from cow manure has a negative carbon score since the methane produced in the digester is captured and hydrogen produced from that methane qualifies for a maximum federal tax credit. |

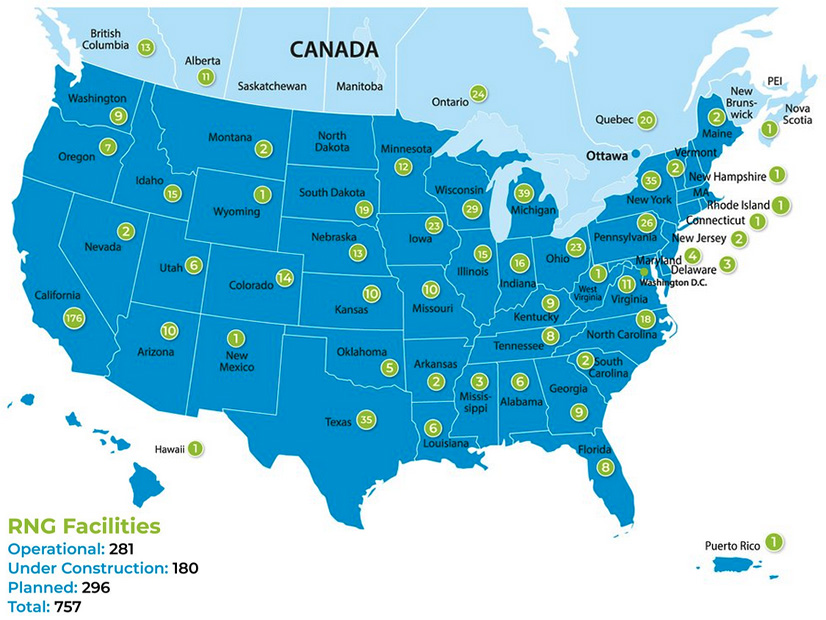

The company has 14 projects operating across the country and others in development.

“We think we’ll produce somewhere around 2.5 million metric tons of carbon dioxide abatement by 2027. We are about a half a million at a run rate right now. Collectively, we’ve got about 200,000 cows across the country that are producing this gas,” he said.

Most of that RNG is injected into pipelines and sent to states such as California and Oregon that have emphasized using the gas as a motor fuel for several years, he said. Revenues from the sale of the gas are augmented by renewable energy credits in the markets that developed under EPA rules. Called renewable identification numbers, the credits travel with the gas.

The company is now looking seriously at hydrogen.

“Hydrogen is an area of particular interest because hydrogen is seen as a next wave of energy usage in the transportation space, as well as just global energy transfer as a whole,” Dvoracek said.