Consultants are evaluating four primary pathways for hydrogen production in California, and they say it’s too soon to eliminate any of them from a long-term strategy for the state’s green hydrogen industry.

Energy and Environmental Economics (E3) is studying the hydrogen production pathways as part of a California Air Resources Board report. The consultants presented initial findings from their analysis during a Feb. 25 CARB workshop.

E3’s analysis focuses on four hydrogen production methods: electrolysis of water using zero-carbon power, steam reformation of methane, methane pyrolysis and biomass gasification. The pathways were chosen based on their relatively high level of technology readiness, according to Vignesh Venugopal, senior managing consultant at E3.

The steam reformation and pyrolysis pathways use methane as a feedstock: either fossil-gas methane or biomethane, which may come from landfill gas, dairy production, organic waste or wastewater treatment. Carbon capture and storage also is evaluated for methods that produce carbon emissions.

E3 found that electrolysis using solar power theoretically could meet California’s 2045 hydrogen demand, which is estimated at 1.6 million metric tons (MT) in CARB’s 2022 climate change scoping plan.

But the resources required for doing so could be a constraint, Venugopal said. About 812 square kilometers of land would be needed for alkaline electrolysis, mainly for solar installations, E3 estimated. That’s more than six times the land area of San Francisco County, which measures 120 square kilometers.

About 72 billion liters of water would be required to meet the 2045 hydrogen demand with alkaline electrolysis, as well as 85 TWh of electricity, which is 28% of California’s current total electricity demand of about 300 TWh.

The land use impacts of electrolysis along with other factors “warrant consideration of other pathways,” according to E3.

“An optimal [hydrogen production] strategy may involve multiple pathways to mitigate impacts and bring benefits to the state,” Venugopal said.

E3’s final analysis will include more details on resource requirements for other hydrogen production pathways.

Meeting Climate Goals

CARB is developing the hydrogen report in response to Senate Bill 1075 of 2022, which states that the legislature’s intent is to develop “a leading green hydrogen industry in California” to realize energy benefits and help meet the state’s climate goals. California has set a goal of net-zero greenhouse gas emissions by 2045.

SB 1075 notes that technological advances may be needed — in addition to scaling up production — to produce hydrogen from renewable feedstock for $1 per kilogram. That’s a target set by the U.S. Department of Energy in its Hydrogen Energy Earthshot, an initiative launched during the Biden administration.

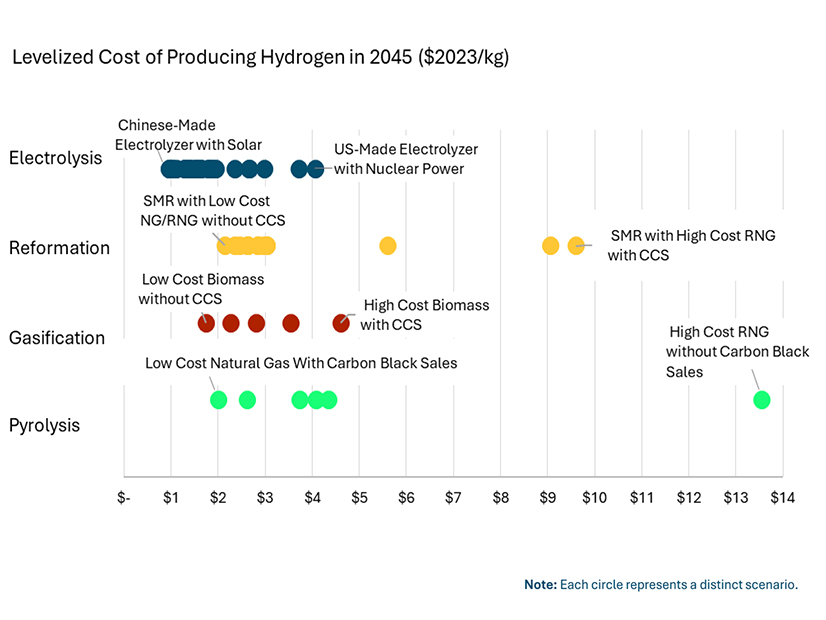

The E3 analysis looked at the cost of producing hydrogen using different pathways and making various assumptions.

With electrolysis, the hydrogen production cost in 2045 could be as low as $1 per kilogram, according to E3. That assumes less expensive electrolyzers from China are paired with low-cost solar energy.

The cost of electrolytic hydrogen rises to over $4 per kg with the use of more expensive, American-made electrolyzers powered by a new nuclear reactor.

For hydrogen produced using steam methane reformation, projected 2045 costs range from $2 to $10 per kg based on the price of natural gas or renewable natural gas (RNG) used. RNG can be costly, depending on its source. Venugopal noted. The high end of the cost range also assumes carbon capture is part of the process.

The cost of natural gas or RNG also is a key factor for hydrogen produced through pyrolysis, which has a cost range of $2 to $14 per kg. In pyrolysis, methane is heated in the absence of oxygen to produce hydrogen and solid carbon. The lower production cost figures in the E3 study assume the solid carbon byproduct can be sold.

Gasification uses heat, steam and oxygen to convert biomass to hydrogen and other products without combustion. E3 estimated the cost to produce hydrogen by this method as ranging from $1.7 to $5 per kg, based on the cost of biomass used and whether carbon capture is deployed. Sources of biomass include forest residue, crop residue and urban wood waste.

Venugopal noted that “a wide range of uncertainty exists” regarding the cost to produce hydrogen in the different pathways.

“There is meaningful overlap between the cost from each pathway, which suggests it is too soon to pick one single pathway based on cost alone,” he said.

Report Timeline

CARB is accepting comments on the hydrogen workshop through March 18.

E3 will continue its analysis, addressing additional topics including the impacts on clean air objectives, barriers to hydrogen use and policy recommendations. The consultant expects to complete the analysis in the third quarter of 2025.

CARB expects to release a draft version of its hydrogen report by the end of 2025, accept public comments and then issue a final report in early 2026.