California is pursuing strategies to recycle lithium-ion batteries as it stakes its clean-energy future on batteries to power millions of electric vehicles and to store thousands of megawatts of solar and wind energy for later use.

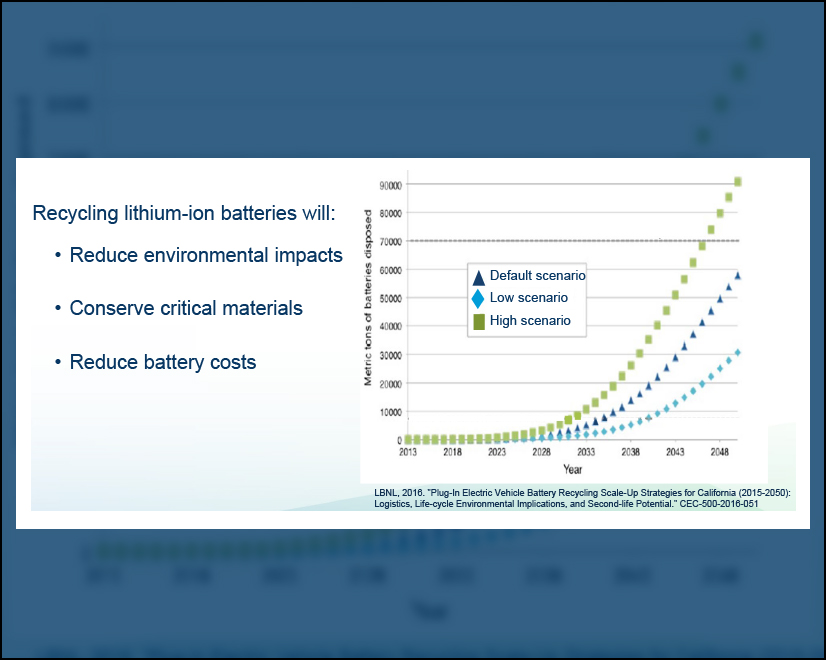

Disposing batteries after they exceed their useful life could prove an environmental quagmire. The state will need to dispose of 60,000 metric tons of batteries filled with toxic chemicals and metals by 2048 under a mid-case scenario, the California Energy Commission (CEC) estimates.

“We need to develop an ecosystem of recycling batteries so that, as we electrify more and more of our transportation system, we don’t have a solid-waste disposal problem,” Commissioner Patty Monahan said during the CEC’s Aug. 11 business meeting.

During the meeting, the commission unanimously approved an initial round of funding for battery recycling projects aimed at reducing the costs and pollutants of current processes.

Today’s “state-of-art [lithium-ion battery] recycling technologies, such as pyrometallurgical and hydrometallurgical processes, suffer from high operational costs and large secondary emissions,” CEC staff wrote.

The CEC awarded $2.7 million in grants under its new effort this year to develop high-value recycling pathways for lithium-ion batteries. Its goal is to help develop technologies that recover more than 95% of the mass of cathode and anode materials and lithium contained in spent batteries.

“The purpose of this [grant] solicitation is to fund applied research-and-development projects that improve and scale high-value recycling processes for lithium-ion batteries, evaluate the performance of recovered materials compared to mined materials, and conduct environmental and economic analyses of battery recycling processes,” the CEC said.

One grant recipient — the University of California, San Diego — has “proposed direct recycling technology [that] holds the potential to address these challenges” but is unproven on a commercial scale, the university said in its grant application. “Improvements in [battery] recycling processes are needed to efficiently recover materials and to produce recycled materials with greater economic value.”

The UC San Diego plan regenerates degraded battery materials, including metals, for use in new batteries. The CEC awarded researchers $1.7 million to scale-up their process and evaluate its effectiveness.

The commission also awarded OnTo Technology more than $1 million for R&D of battery recycling processes that allow new batteries to be made with 100% recycled electrodes.

OnTo plans to collect used batteries to demonstrate its “cathode healing” process and to “scale-up capacity to be able to handle multiple kilograms per day with potential for further increases in the future,” said Ben Wender, an electric generation system program specialist in the CEC’s Energy Research and Development Division. “The project will partner with battery manufacturers to … produce new batteries with high-recycled content and compare their performance to batteries made from mined materials.”

The grants fall under the commission’s Electric Program Investment Charge (EPIC), which distributes more than $130 million in ratepayer charges annually to R&D.

CEC Chair David Hochschild said the recycling effort “dovetails very nicely” with the commission’s project to extract lithium for batteries from geothermal generation near the Salton Sea in Southern California. (See California Lithium Extraction Plan Advances and GM Invests Big in Calif. ‘Near Zero’ Lithium Project.)

“These two things need to proceed in parallel, both strengthening and building up the lithium recycling ecosystem and recovery efforts in the Salton Sea,” he said.