The Biden administration’s efforts to develop a hydrogen market — from the generation of clean hydrogen to its use as a universal fuel across the economy — has expanded as if on a war footing, focusing the firepower of the National Labs alongside that of multiple industries and universities.

That was made clear this week at the U.S. Department of Energy’s three-day virtual symposium, which attracted thousands of engineers, scientists and curious members of the public, and covered every aspect of what has become a rush to move the nation from fossil fuel to hydrogen energy.

Even before President Biden unveiled the administration’s goals in a series of speeches during the first weeks of his term, DOE had in late 2020 published an updated hydrogen plan that predicted the federal push to combat climate change by moving the nation to hydrogen. That plan was an update on previous, but much less ambitious, plans dating back to 2002.

The accelerated efforts under this administration have even surprised Sunita Satyapal, director of the Hydrogen and Fuel Cell Technologies Office within DOE’s Office of Energy Efficiency and Renewable Energy (EERE). She was moderator of the initial plenary session on Monday that took a quick look at the hydrogen effort, from basic science to deployment.

“Keeping track of all the information out there because things are moving so quickly” has become difficult, Satyapal said. “There are so many offices, so much happening in the space.

“Please do keep track of the websites and newsletters,” she advised viewers and listeners before introducing Todd Shrader, head of one of DOE’s newest operations, the Office of Clean Energy Demonstrations. “What are the priorities that stakeholders out there should pay attention to from your perspective?” she asked.

Shrader’s response: “What’s it going to take to launch the new hydrogen economy itself?” he replied. “We can build hydrogen hubs 1 through 4, or 1 through 5 with government support,” he said in a reference to the department’s offer of up to $2 billion in matching grants to regions capable of cooperating to build regional developments producing clean hydrogen for use by nearby industries.

“But what’s it going to take to build plants 6 to 100? What’s it going to take to move to these [administration] goals by 2035 and 2050?” he said in a reference to the administration’s goal of building a carbon-pollution free U.S. power grid by 2035 and a net-zero carbon economy by 2050.

But producing hydrogen, whether by electrolysis with renewable energy or by splitting it from methane and capturing the resulting carbon dioxide, is a complex process.

Ned Stetson, a veteran hydrogen technologies researcher and now program manager at DOE, made that clear when explaining the efforts of his research team at EERE to develop electrolyzer and related technologies to produce hydrogen at a price comparable to steam reforming and ultimately even lower.

Steam reforming today produces about 99% of the hydrogen used by industry, and one reason is that electrolyzer technology, from efficiency to durability, cannot compete. Helping industry develop more efficient and more durable electrolysis technology is near the top of Stetson’s list. But it’s not alone.

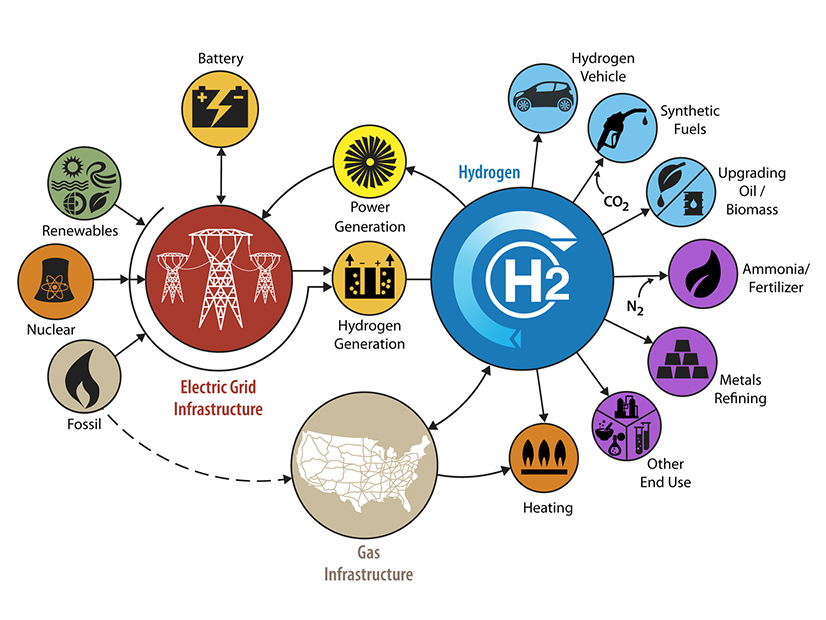

“We cover everything from reducing the hydrogen molecule; to all the infrastructure needed to condition it, move it, store it and dispense it; to all these various end-use applications for power generation, industrial applications and so forth,” he said.

“We are also involved with blending hydrogen with the natural gas infrastructure, and in terms of transportation, we’re also developing the onboard storage technologies. So it’s a very large activity covering a lot of distance.

“We are really focused in our office on using the clean and sustainable energy resources and feed stocks to produce clean hydrogen. We look at several key pathways producing hydrogen, including direct solar water splitting, biological processes and, of course, electrolysis. And then once you produce the molecule, we work on the conditioning, liquefying it … purifying it, moving it, storing it and then finally dispensing it to the new application,” he said.

The Infrastructure Investment and Jobs Act has provided $1 billion in research and development funds for electrolysis, he said. The ultimate goal is reduce the price of hydrogen produced through electrolysis to $1/kg by 2031.

“The goal of the electrolysis program is reducing the cost of hydrogen produced with electrolyzers to less than $2/kg by 2026. That’s right in line with getting to $1 by 2031,” he said.

After asking for input in February from industry and other researchers about how these goals might be accomplished, the division received comments from 120 companies and individuals, he said.

“We asked about the key attributes for storage and infrastructure, the ancillary technologies, what would be some of the barriers for scale up. What are the needs for national test facilities for electrolyzers? We asked about recommendations to incorporate … diversity and equity. We got a lot of input from … manufacturers and developers including universities and a lot of end users and stakeholders,” he said. “We’re still digesting all the information.”

An example of DOE working with industry is its contract with Shell in October 2021 to develop very large liquid hydrogen storage tanks. Such tanks will be important for domestic storage and at export terminals.

“Shell is looking at designing … an extremely large liquid hydrogen storage vessel, 20,000 to 100,000-cubic-meter storage vessels. To put that in perspective, currently the largest liquid hydrogen storage vessel, just constructed at the Kennedy Space Center, and is about 4,700 cubic meters,” Stetson said.

Dimitrios Papageorgopoulos, program manager at DOE’s Fuel Cell Technologies, provided some perspective on the depth of the agency’s involvement in efforts to help industry develop fuel cell power systems capable of competing in, for example, heavy trucking, power generation or infallible standby generation.

“The goal is to develop fuel cells that are competitive with incumbent and emerging technologies across all these applications. The goal is to develop these fuel cells to meet market needs, and this is very important because we’re not looking to develop a technology for the sake of technology,” he said.