With tech giants Google and Amazon turning to small modular reactors to power their megawatt-guzzling data centers, the U.S. Department of Energy is doubling down on its efforts to build out a domestic supply chain for the high-assay, low-enriched uranium (HALEU) these advanced reactors will need.

In a series of recent announcements, DOE awarded 10 contracts covering two of the key stages of the nuclear fuel production cycle ― enrichment and deconversion ― and released its final environmental impact statement (EIS) aimed at accelerating the development of such facilities.

The goal, according to the EIS, is to produce 290 metric tons — that’s 639,341 pounds — of HALEU over the next 10 years. Doing so by expanding existing enrichment and deconversion facilities could have the lowest level of environmental impacts, the EIS says.

Announced Oct. 17, four of the DOE contracts will help to expand HALEU enrichment capacity, while the other six contracts, for deconversion, were announced Oct. 8. Each of these companies will be negotiating with DOE for 10-year contracts for a minimum amount of $2 million, with additional billions in funding available for enrichment and deconversion services.

According to a DOE press release, the multiple awards will create “strong competition … allowing DOE to select the best fit for future work,” while building “a strong, reliable domestic nuclear fuel supply chain free of influence from adversarial foreign nations.”

The U.S. has a well-established supply chain for the low-enriched uranium (LEU) used in the country’s existing fleet of 95 light-water reactors, including two new units at the Vogtle nuclear power plant in Georgia, which came online this year.

Prior to Russia’s 2022 invasion of Ukraine, the U.S. was dependent on a single company in Russia for its supply of HALEU. Building out a domestic supply chain quickly became a bipartisan priority, and Congress passed a law prohibiting such uranium imports from Russia, which President Joe Biden signed in May.

The war in Ukraine, coupled with the boom in electricity demand driven by data centers, has created a “muscular resurgence” of interest in nuclear, National Climate Advisor Ali Zaidi said in a DOE press release on the enrichment contracts.

The four companies receiving the enrichment contracts are Louisiana Energy Services, Orano Federal Services, General Matter and American Centrifuge Operating (ACO).

Orano was also chosen for a deconversion contract, and ACO is a subsidiary of Centrus, another deconversion awardee. The other four on this list are BWX Technologies, Framatome, GE Vernova and Westinghouse.

Most of the companies have extensive experience as either developers of advanced reactors or suppliers of nuclear fuel and will be expanding existing facilities or, in the case of Orano, building new ones.

ACO has already been producing small amounts of HALEU under a DOE-funded demonstration project, while Orano recently announced its plans for building a state-of-the-art enrichment facility on a site owned by DOE in Oak Ridge, Tenn.

In a Centrus press release, CEO Amir Vexler said the enrichment contract will help the company expand its HALEU production capacity “so that we can restore a robust, American-owned uranium enrichment capability to power the future of nuclear energy.”

ACO’s own domestic supply chain for the equipment it will need for enrichment includes 14 U.S. suppliers in 13 states, the company said.

HALEU 101

Nuclear fuels are classified based on their concentrations of the “fissile” U-235 isotope used to trigger or maintain the nuclear reactions that produce energy. The concentration for LEU fuel is 3 to 5%, while for HALEU, it is 5 to 19.75%.

A higher concentration of fissile material means reactors fueled with HALEU can be smaller, with smaller fuel cores, but still produce high levels of energy. The fuel cores also will last longer ― requiring less refueling ― and the reactors can operate more efficiently and produce less radioactive spent fuel to be stored.

On the downside, the World Nuclear Association notes that the various parts of the HALEU fuel cycle will cost more and, in the U.S., will require separate licensing from the Nuclear Regulatory Commission (NRC).

The NRC notes that it licensed the Centrus pilot program and has also licensed HALEU used by a Navy test reactor. The commission is also “actively reviewing license applications for fuel enrichment facilities and fuel fabrication facilities to produce and utilize HALEU.”

For example, Louisiana Energy Services is a subsidiary of Urenco, another nuclear fuel provider that has an enrichment facility in New Mexico. According to Urenco, the DOE contract will allow it to expand the New Mexico plant, but additional licensing from the NRC will be needed.

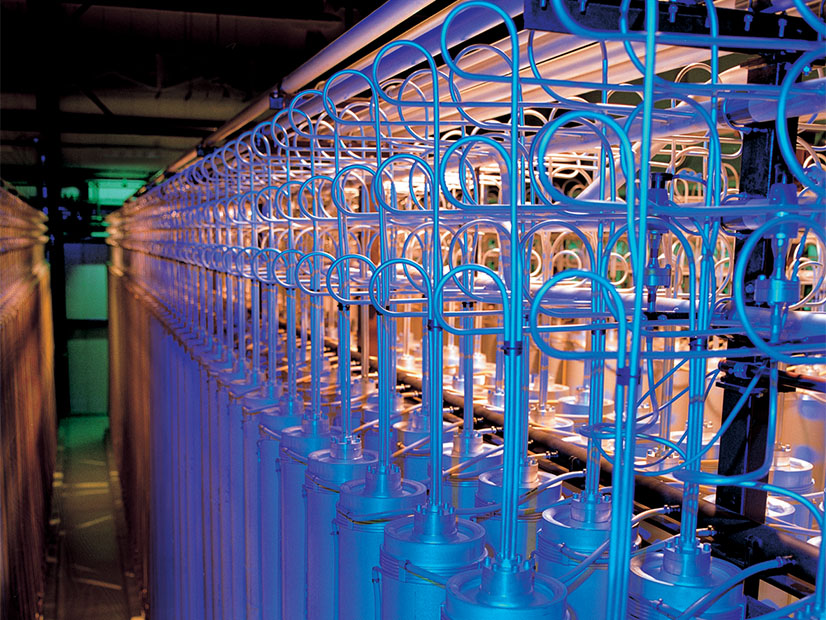

The nuclear fuel cycle starts with mined uranium, which contains less than 1% of the fissile U-235 isotope and more than 99% of the heavier, nonfissile U-238 isotope. The enrichment process runs mined and milled uranium, called yellowcake, through a series of centrifuges, which spin out the heavier U-238 isotopes, automatically increasing the concentrations of U-235.

Patrick White, research director of the Nuclear Innovation Alliance, noted that the extra processing to get from LEU concentrations of U-235 to the higher HALEU concentrations might require a relatively modest expansion of an existing facility.

The more concentrated uranium produced by enrichment is smaller in size, making further concentration easier, he said.

“The amount of enrichment facilities that you need for lower enrichment is going to be much greater than the amount of enrichment facilities you’re going to need to do higher enrichment because it’s a lot more work to do those initial steps of concentrating because you’re managing such a large volume of material,” White said.

“Essentially, it takes much less work to go from 5 to 20% [enrichment] than it does to go from natural uranium to 5%,” he said.

The enriched uranium, in the form of uranium hexafluoride (UF6), is then further processed, or deconverted, into one of two forms of uranium used in fuel cores, uranium oxide (UO2) or metallic uranium, in both cases via a chemical process.

Deconversion facilities for UO2 already exist for LEU production, but White said, they are not “rated for and compatible with HALEU, so they will need to develop new infrastructure for HALEU deconversion.”

TerraPower, which will use metallic uranium as fuel stock for its Natrium reactor, has partnered with Framatome to build a pilot plant for metallization, located at Framatome’s existing nuclear fuel plant in Richland, Wash.

Economies of Scale

But will the U.S. need 290 MT of HALEU over the next 10 years?

DOE’s Advanced Reactor Demonstration Program is funding the development of two advanced reactors ― TerraPower’s Natrium reactor and X-energy’s Xe-100 ― which will each need between 20 MT and 25 MT of HALEU per year, according to a department spokesperson.

But beyond these demonstrations, the power demand from hyperscale data centers running artificial intelligence could provide the market needed for broad commercialization.

On Oct. 14, Google and Kairos Power signed an agreement to develop a fleet of SMRs that will be able to provide 500 MW of power by 2035. Amazon’s investment in X-energy, announced Oct. 16, is aimed at putting 5 GW of new power on the grid by 2039.

In addition, DOE is now accepting applications for $900 million in funding for the development of first-of-a-kind SMRs that will generate a string of orders.

White sees the DOE contracts and other programs as a means to create economies of scale for HALEU production and provide a buffer for any disconnect of supply and demand.

“How much material do we need to procure to actually make reasonable investments in production?” he asked. “One of the challenges with any of these systems, whether it’s the enrichment facilities or whether it’s the deconversion facilities, is that they really are subject to economies of scale. Producing one kilogram of HALEU costs a heck of a lot more on a per unit basis than producing one MT or 10 MT.”