Quality-control problems affect a sizable number of new energy storage systems, creating potential safety and performance risks, a new report indicates.

Clean Energy Associates (CEA) based its conclusions on an extensive series of audits over six years.

CEA found 18% of inspected lithium-ion battery energy storage systems (BESS) had quality issues related to their thermal management system and 26% had issues related to their fire detection and suppression system.

CEA suggested the industry is focusing too closely on cell selection and said it should not overlook system integration as a potential source of problems. Nearly 50% of the defects CEA found were at the system level.

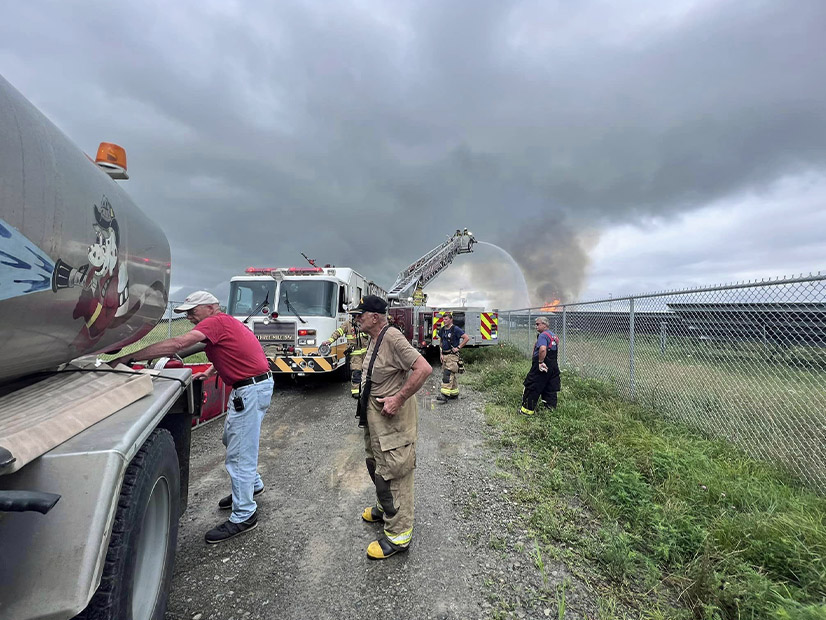

The report, “BESS Quality Risks,” comes amid an extensive buildout of BESS and a lingering public uneasiness about the safety of these systems. Fires are hard to extinguish and can emit toxic fumes.

The advisory and engineering services firm conducted more than 320 quality audits at over 52 BESS factories on systems that comprise more than 30 GWh of capacity. It found more than 1,300 problems.

CEA said the defects it found were split nearly equally between components — cells or modules — and systems. The integration of components into a system is subject to less stringent quality-control procedures, it said, even though it is a highly manual and labor-intensive process.

Meanwhile, the systems themselves are highly complex and vulnerable to component defects missed in earlier quality checks.

Other system-level findings in the report broke down as follows:

-

- 8% were performance-related, due to manufacturing defects and/or integration errors. This led to problems such as diminished capacity and round-trip efficiency results due to large temperature and voltage variations among cells within a module, thanks to poorly welded wiring connections.

- 34% were enclosure-related, due to manufacturing defects or damage sustained in transportation. These included poor rigidity, weakness, deformation, grounding defects, water ingress, cosmetic problems, and poor wiring or cabling.

- 58% were related to the balance of system — various defects in components or errors in their integration. These included coolant leakage from a variety of causes; malfunctioning sensors and alarms due to miswiring; and exposure of a live conductor within the AC/DC distribution.

- Common fire suppression system defects included nonfunctioning release actuators for the fire-extinguishing agent due to a faulty diode; nonfunctional fire alarm abort buttons due to miswiring; and nonresponsive smoke and temperature sensors, also due to miswiring. These defects pose a risk of fire and explosion, or of serious equipment damage due to unnecessary activation of the fire control system.

- Common thermal management system defects included circulation system component failures due to fasteners being not tightened enough, leaving a loose connection, or over-tightened and deforming flange plates; and compressor mainboard short circuiting due to a burned metal oxide semiconductor tube. These defects pose a risk of thermal runaway or accelerated battery degradation.

- Battery cell defects were attributed fairly evenly among electrode manufacturing, cell assembly and cell finishing.

- Module defects were heavily attributed to sorting and installation (45%) and interconnection welding (41%); enclosing and end-of-line testing issues were less common.