ISO-NE provided stakeholders with additional detail on its plans for modeling capacity demand and resource reliability attributes as the RTO and stakeholders continued work on the resource capacity accreditation (RCA) project at the NEPOOL Reliability Committee meeting Jan. 16.

“Improvements are required to the Resource Adequacy Assessment (RAA) used currently to calculate capacity requirements (demand) and develop resource-specific accreditation values,” said Fei Zeng, ISO-NE technical manager.

ISO-NE is working to improve the RAA modeling to better assess the risks and severity of loss-of-load events, and how different resources would affect system reliability during these periods. The RTO is trying to better capture resource reliability performance under different weather and system loading conditions, and with different resource mixes.

The RAA resource modeling includes specific cases focused on season risk, resource accreditation, and system and zonal capacity requirements.

ISO-NE has outlined four different modeling options for different resource types: thermal modeling based on seasonal qualified capacity and outage rate; profile modeling based on an “hourly expected performance profile;” storage modeling based on expected energy limitations; and perfect capacity modeling, based on seasonal qualified capacity.

At the January RC meeting, Zeng detailed which modeling options would be used for different resource types:

-

- Thermal model: nuclear, coal, fuel cell, nonintermittent hydro, imports, tie benefits, and (from March to November) gas and oil resources.

- Profile model: active and passive demand resources, and intermittent resources like solar, wind and landfill gas.

- Storage model: battery storage and pumped hydro.

- Perfect capacity model: distributed energy capacity resources and co-located generators that function as a single capacity resource.

For peak winter months, ISO-NE is proposing to take a more varied approach to modeling oil, gas and dual-fuel resources, instead of just using the thermal model, which would apply to them in all other months.

From December through February, gas resources would be modeled as a single fleet using the profile model, intended to account for gas network limitations and demand from local gas distribution companies.

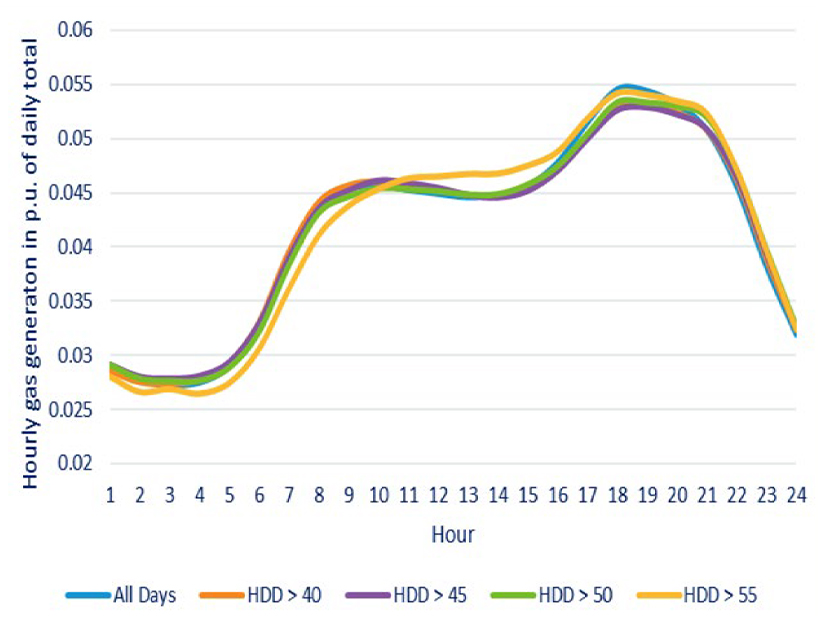

“A regression model is used to establish a relationship between the amount of daily gas available to generation and temperature conditions based on historical data,” Zeng said. “The daily available gas will be apportioned to each hour during the day based on historical hourly gas generation patterns and the representative heat rate of the gas fleet.”

For oil resources, ISO-NE proposes using the thermal model for residual fuel oil (RFO) resources in all RAA cases and for distillate fuel oil (DFO) resources in the accreditation and capacity RAA cases.

For the RAA seasonal risk assessment, ISO-NE would model DFO resources as an “aggregate energy storage resource with a limited amount of energy available during a two-week period.”

Zeng noted that DFO resources have smaller storage tanks than RFO resources, causing them to exhaust their stored fuel more quickly and require more frequent replenishment. Because of variability in tank sizes and replenishment strategies, “DFO resource risks are better captured on a fleet level,” Zeng said.

The two-week DFO energy constraint would be based on data from the past five winters.

Fuel Requirements

To compare the reliability benefits of different types of resources that rely on a limited supply of energy, ISO-NE proposes creating a “daily operating hours requirement” (DOHR), which would equal the number of hours per day a resource must be able to operate at its seasonal capacity rating during peak winter months. Resources that can’t meet this requirement would have their qualified capacity derated.

The RTO would use RAA results to calculate the daily operating requirement and would update the requirement at each capacity auction. ISO-NE also is considering a winter peak seasonal operating hours requirement (SOHR) and a fuel storage hours requirement (FSHR) for stored fuel resources. The calculation of SOHR and FSHR would consider RAA results and historical weather data.

FSHR would be calculated by “multiplying the DOHR by the number of days in a winter cold snap,” said Alex Mattfolk of Levitan & Associates (LAI), which is working as a consultant for ISO-NE on the project. For this calculation, the consulting firm has determined that modeling a four-day cold snap would cover more than 99% of days.

The seasonal requirement would be determined by multiplying the DOHR by the number of days cold enough to significantly stress the grid. LAI determined that 11 days would cover over 99% of days.

Operationally Limited Resources

Mattfolk also presented on the firm’s proposal for “operationally limited resources” — gas plants that typically are unable to run on cold days due to “physical and/or operational constraints on gas delivery.” These resources would not be credited with any qualified capacity.

LAI proposes to flag operationally limited resources based on historical performance during cold periods. Flagged resources could appeal their designation by providing evidence the gas constraint no longer applies or that the lack of operations was due to some unrelated factor.